Introduction

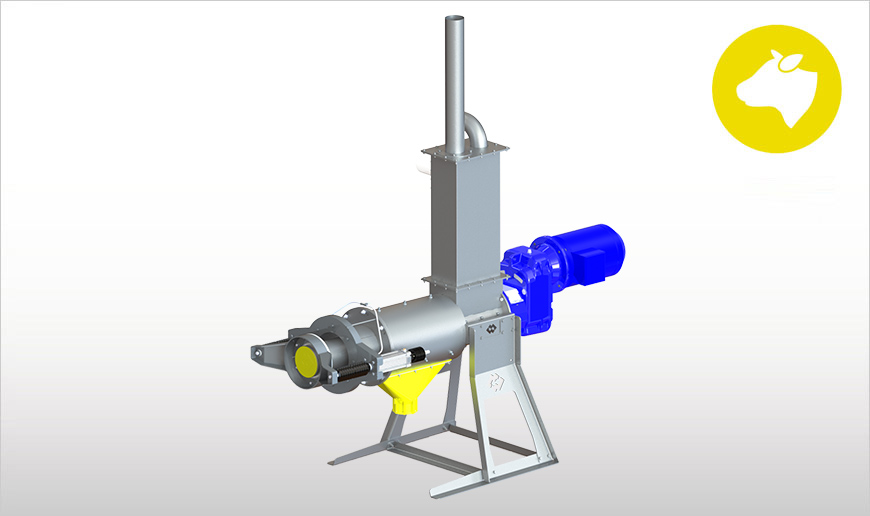

SEPCOM Bedding is an innovative screw press solids-liquid separator.

Thanks to its special features like the compensator hopper tank, the self-adjusting pneumatic pressor and its long-life components, SEPCOM Bedding can be a standalone solution for green bedding purposes.

Significant savings on bedding material and reduction in overall costs

High separation efficiency and high dry solids content

Technical Specs

Description

The separator consists of a feeding section provided with compensator tank and overflow hopper. The stainless steel casing includes a conveyor screw (inside a cylindrical screen basket) for material transport towards the outlet. The screen provides the separation of the solid from the liquid phase flowing through by pushing the solids towards the outlet where two counter-pressure diaphragms generate a material plug. This allows automatic operation of the separator and avoids flushing through of the liquid phase.

The drive unit consists of an electric motor and a gear reducer equipped with a splined output shaft which is directly coupled to the conveyor screw.

The whole system is ruled by a control unit that adjust the counter pressure on the plug depending on the dry matter of the raw material to treat, this automation allows a constant dryness on the separated solid.

SEPCOM Bedding is particularly specialized for cow manure or digestate treatment.

Function

SEPCOM Bedding is a solids-liquid separator based on screw conveyor technology. Performing separation by both gravity and mechanical compression, the machine is designed to separate the liquid phase from the solid phase of cow manure or digestate for green bedding purposes.

Features

- Stainless steel hopper with overflow for a constant head and operation

- Simple in operation and cost-saving in spare parts

- Self-adjusting counter-pressure pneumatic outlet

- Suitable for continuous duty

- Max hydraulic throughput 20 m3/h

- Dry matter for separated solid >34%

- Dry matter for separated liquid < 5%

Benefits

- High performance wear-resistant screen basket

- Significant overall cost reduction on cow bedding

- Significantly reduced assembly and maintenance time

- Affordable spare parts

- Fully automated

Options

- From 0.75 to 0.90 mm screen basket slot sizes

- Full control unit for all devices in a separation plant or Easy control unit (only for pneumatic pressor)